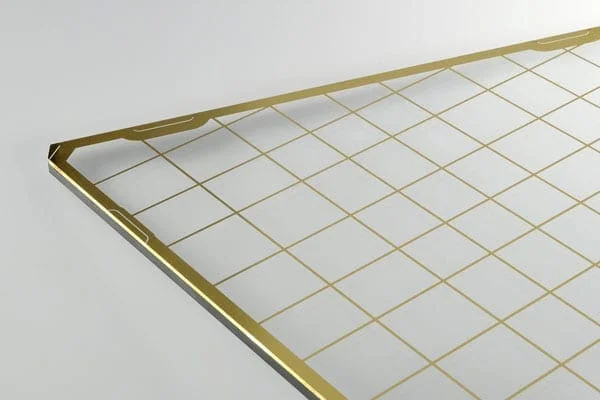

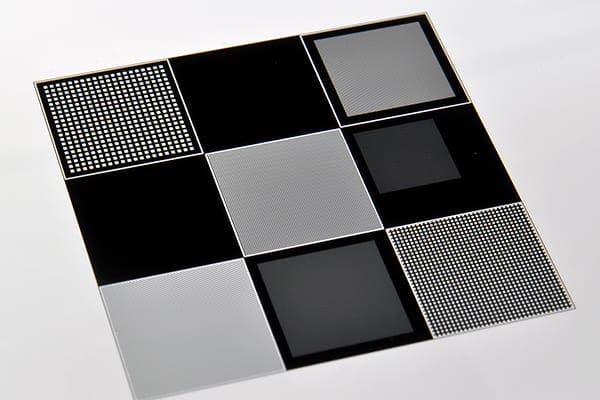

Custom Precision Optical Patterns

Other Custom Pattern Projects

Opto-Line is synonymous with customization. We are proud to deliver some of the most difficult custom optical pattern designs that that require a very high degree of precision, experience and ingenuity.

We’ve worked with universities, ophthalmologists, scientists, electrical engineers, energy development companies, and a plethora of other industries to create custom patterns on their optics (or substrates procured by Opto-Line). Typically one part of a larger component, our patterned optics are critical to our customers’ final product.

Vacuum evaporation is the process of causing the pressure in a liquid-filled container to be reduced below the vapor pressure of the liquid, causing the liquid to evaporate at a lower temperature than normal. Vacuum evaporation is also a form of physical vapor deposition used in the semiconductor, microelectronics, and optical industries and in this context is a process of depositing thin films of material onto surfaces. Such a technique consists of pumping a vacuum chamber to pressures of less than 10−5 torr and heating a material to produce a flux of vapor in order to deposit the material onto a surface. The material to be vaporized is typically heated until its vapor pressure is high enough to produce a flux of several Angstroms per second by using an electrically resistive heater or bombardment by a high voltage beam.

We'd love to hear from you. Please tell us more about your custom optical pattern needs.

Tags: optical pattern design custom optical patterns custom precision patterns