Opto-Line offers unparalleled service and undeniable quality. To learn more about how we can meet your custom optical pattern needs, please call us at 978.658.7255 or request a quote by clicking below.

Opto-Line offers unparalleled service and undeniable quality. To learn more about how we can meet your custom optical pattern needs, please call us at 978.658.7255 or request a quote by clicking below.

From Resolution Test Targets and EMI Grids to Beam Splitters, Multi-Density Resolution Masks and other Custom Pattern projects, Opto-Line can manufacture your unique, custom patterns on optical substrates per your requirements. We look forward to learning more about your your precision optical patterns needs and discussing how our custom services and solutions can help.

Opto-Line works closely with our clients in a wide variety of industries and creates custom solutions to fit their needs. One specialty that separates Opto-Line from other companies is our ability to put precision patterns on lenses, both concave and convex. Feasibility depends on the radius and the feature sizes. Please call (978) 658-7255 or […]

Often times our custom patterns are vital in the R&D phase of a product. Opto-Line has a long history of partnering with companies across an array of industries to help them achieve their product’s research and development goals. For more than 50 years, the Opto-Line name is synonymous with the highest quality service. We invite […]

Opto-Line’s services include multi-density resolution masks, neutral density filters, reticle patterns, precision apertures, calibration test targets, EMI grids, photolithographic services, contrast test targets, and many more. Patterns can be made from various materials such as chrome, low-reflecting black chrome, gold, aluminum, SiO2 and more.

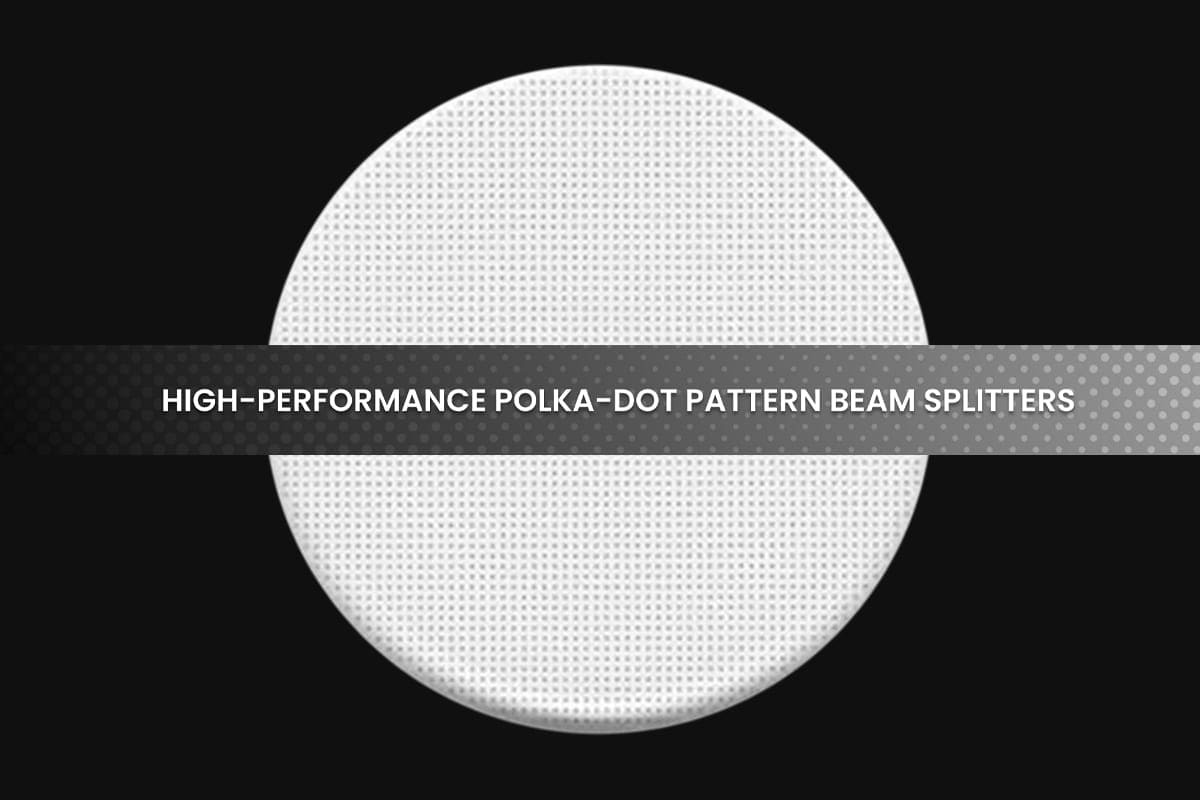

Opto-Line’s beam splitters can divide a beam of light or other electromagnetic radiation into two or more separate beams. These beam splitters are ideal for use with broadband, extended sources, such as tungsten, halogen, deuterium, and xenon lamps, and for use in monochromators, spectrophotometers, and other optical systems. As industry leaders in the manufacturing of […]

Opto-Line International Creating Custom Precision Patterns on Optics Since 1967 Opto-Line is not your standard, stock reticle company. We manufacture your unique, custom patterns on optical substrates per your requirements. From reticles and apertures to multi-density resolution masks and almost any pattern imaginable, our photolithography and thin film coatings practices are optimized to create your […]

Opto-Line International’s expertise in photolithography, combined with our thin film coating capability, enables us to provide our customers with the finest precision patterned optics…often the most complex and demanding. Serving hundreds of world-wide markets from aerospace to clean energy, we invite you to reach out to discuss your needs for the year ahead.

Providing solutions for our Military and Defense industry clients’ custom patterned optical needs. Opto-Line is proud to manufacture parts used for the United States’ defensive systems as we take great pride in our work and service. Reach out today to learn more!

Opto-Line’s beam splitters can divide a beam of light or other electromagnetic radiation into two or more separate beams. These beam splitters are ideal for use with broadband, extended sources, such as tungsten, halogen, deuterium, and xenon lamps, and for use in monochromators, spectrophotometers, and other optical systems. As industry leaders in the manufacturing of […]