Combined with our specialized photolithography, Opto-Line utilizes thin film coatings to make your custom patterns. Some examples of our custom patterning capabilities include reticles, resolution test targets, EMI grids, apertures, linear scales, and neutral density step tablets. Opto-Line can typically tackle any custom pattern imaginable.

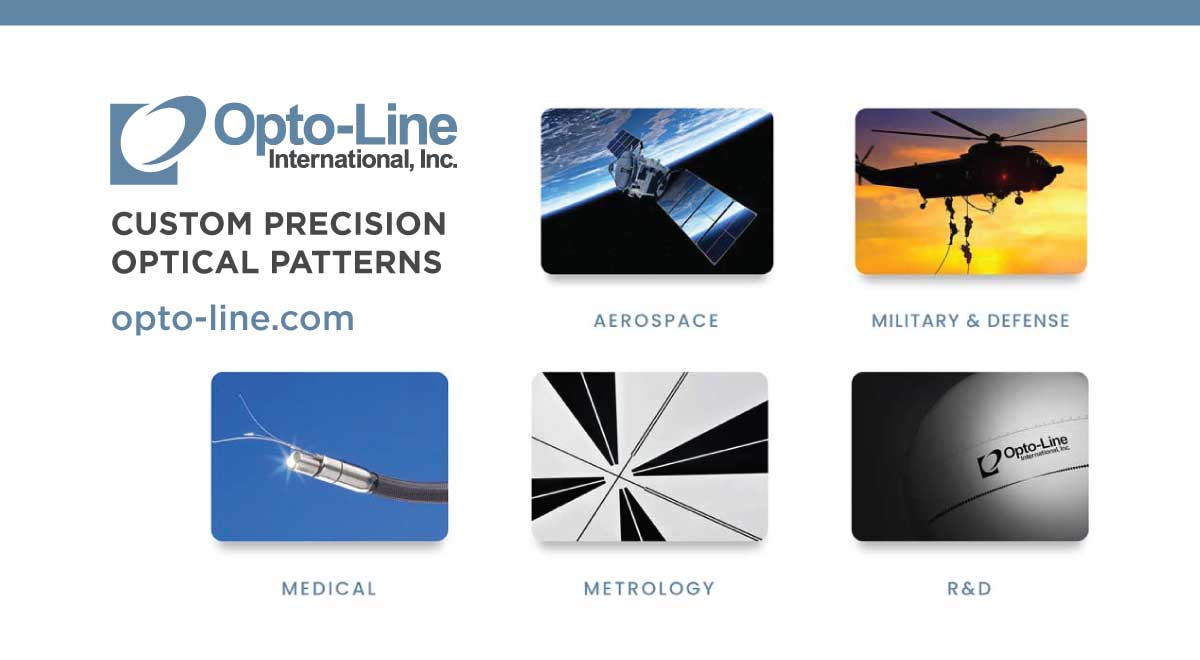

As industry leaders in the manufacturing of precision reticles, Opto-Line International’s services include multi-density resolution masks, neutral density filters, reticle patterns, precision apertures, calibration test targets, EMI grids, photolithographic services, contrast test targets, and many more. We proudly serve hundreds of world-wide markets from aerospace to endoscopy. Learn more about the industries to whom we […]

Opto-Line International has been creating custom precision patterns on optics since 1967. We’d love to hear about your custom reticle needs and invite you to learn more today. From reticles and apertures to multi-density resolution masks and almost any pattern imaginable, our photolithography and thin film coatings practices are optimized to create your final parts.

Opto-Line International has been creating Custom Precision Patterns on Optics Since 1967. As industry leaders in the manufacturing of precision reticles, we provide companies in the medical, optometry, aerospace, industrial, science and defense sectors with the very best custom precision optical patterns and thin film coatings available.

We are industry leaders in the manufacturing of precision reticles. Opto-Line International’s services include multi-density resolution masks, neutral density filters, reticle patterns, precision apertures, calibration test targets, EMI grids, photolithographic services, contrast test targets, and many more. Patterns can be made from various materials such as chrome, low-reflecting black chrome, gold, aluminum, SiO2 and more.

Cleanliness and the careful handling of sensitive optical components is of the highest importance for every employee. Opto-Line International takes tremendous pride in the high level of quality achieved during the manufacture of these products at our state of the art facility. Our modern equipment, including multiple high-vacuum evaporation chambers and a Class 100 clean […]

Our custom patterns are often vital components in the R&D phase of a product. Opto-Line’s ability to develop innovative solutions for the most difficult projects is what makes us the premier vendor to call upon for your research needs. We have a long history of partnering with companies across an array of industries to help […]

Often times our custom patterns are vital in the R&D phase of a product. Opto-Line has a long history of partnering with companies across an array of industries to help them achieve their product’s research and development goals. For more than 50 years, the Opto-Line name is synonymous with the highest quality service. We invite […]

Opto-Line International’s services include multi-density resolution masks, neutral density filters, reticle patterns, precision apertures, calibration test targets, EMI grids, photolithographic services, contrast test targets, and many more. Patterns can be made from various materials such as chrome, low-reflecting black chrome, gold, aluminum, SiO2 and more.

Often times our custom patterns are vital in the R&D phase of a product. Opto-Line’s ability to think out of the box and tackle the most difficult projects is what makes us the premier vendor to call upon for your research needs. We have a long history of partnering with companies across an array of […]