OPTO-LINE INSIGHTS

Welcome to the Opto-Line Blog

It is our mission to provide optimum solutions for our clients’ Optical Pattern needs in the areas of Research and Development.

Opto-Line has a long history of partnering with many companies over the years to help them achieve their product goals. Often times our custom patterns are vital in the R&D phase of a product. Opto-Line’s ability to think out of the box and tackle the most...

Opto-Line’s custom precision optical patterns are used in thousands of products and systems throughout the world. Reach out today to learn more!

Just a few applications for our patterning solutions include satellite navigation systems, endoscopes, optometry, modulated contrast microscope objectives, electro-optical devices, optical system calibration, photolithographic systems, surveillance systems, and...

Opto-Line provides precision optical metrology solutions and components for universities and the scientific community.

From 1951 USAF targets to many custom reticles and resolution targets, Opto-Line’s Metrology services provide precision components for calibration, measurements and alignments. [button...

Opto-Line ensures your custom pattern optical project will meet our strict quality control measures for precision patterning and exceptional quality.

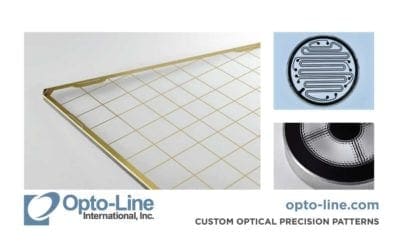

Some examples of our custom patterning capabilities include apertures, reticles, resolution test targets, EMI grids, linear scales, and neutral density step tablets. Opto-Line can typically tackle any custom pattern imaginable. [button...

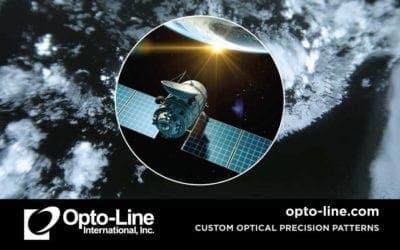

Opto-Line’s custom optical patterning, most recently playing a vital role in Perseverance’s mission to Mars, is used for sun angle sensor systems on satellites and other aerospace applications.

Our very durable low-reflecting black chrome combined with extremely high precision patterns is what sets Opto-Line apart. Learn more about our...

Opto-Line International’s custom precision patterning proves to be paramount in the critical positioning and trajectory of Perseverance for re-entry on Mars.

The Sun sensors, manufactured by Adcole Space, contain Optical Reticles manufactured by Opto-Line.

Our high quality apertures for medical endoscopes provide excellent edge acuity and accuracy. Opto-Line is here to address each customers’ needs on a project by project basis. Reach out today to learn more.

Typically utilizing our proprietary low-reflecting black chrome, our apertures have become the benchmark for endoscope manufacturers. Our black chrome is very durable, low-reflecting in visible with Rave <5% , OD > 4.0. Excellent edge acuity and accuracy (±...

Opto-Line is proud to manufacture parts used for the United States’ defensive systems including high-end EMI grids on IR material, lenses, prisms, and many other non-standard substrates.

The critical nature and accuracy of our patterns cannot be understated. This is fundamental to the work we do here at Opto-Line. Our reputation is built upon it and our success depends on it. To learn more about our high-end EMI grids, reach out to Opto-Line today....

We help clients with a variety of custom pattern projects, working with universities, ophthalmologists, scientists, electrical engineers, energy development companies, and a plethora of other industries

Opto-Line Offers Custom Services and Solutions for your Precision Optical Pattern Needs While our precision patterns are made via thin film coatings, we are not a coating house. Instead we focus and specialize in the custom patterning service our clients require on a...

Opto-Line offers the highest quality blanket photoresist coating services for our clients and can provide custom photoresist patterns on a wide variety of substrates and silicon wafers.

Our blanket photoresist coating services for semiconductor test wafers are processed in a dedicated, class 100 cleanroom. We'd love to hear from you. Please tell us more about your custom optical pattern needs. [button link="https://opto-line.com/contact/"...