OPTO-LINE INSIGHTS

Welcome to the Opto-Line Blog

Opto-Line’s Precision Patterns and Thin Film Coatings are custom crafted with exceptional quality. For over fifty years, the Opto-Line name has been synonymous with service.

Precision Patterns Some examples of our custom patterning capabilities include reticles, resolution test targets, EMI grids, apertures, linear scales, and neutral density step tablets. Opto-Line can typically tackle any custom pattern imaginable. Thin Film Coating...

Opto-Line has been a trusted partner with companies in the Aerospace industry for custom patterned lenses and coatings for a variety of Aerospace applications.

But it is not only the coating that separates Opto-Line from other companies but the precision we can accomplish in the detailed patterns. Opto-Line has provided various custom patterns typically utilizing our low-reflecting black chrome. For Aerospace applications,...

Opto-Line International provides the highest quality blanket photoresist coatings and photoresist patterns on wafers and various custom optics. Visit https://opto-line.com/ to learn more.

Utilizing a semi-automated coating system allows us to provide our clients with an extremely quick lead time and a high quality coating. Please contact us so we can learn more about your custom optical pattern needs. [button...

It is with great pride that we partner with clients in the Military and Defense industries as we observe and honor those who have served and sacrificed this Memorial Day.

Opto-Line is proud to manufacture parts used for the United States’ defensive systems and remain dedicated to excellence for our work and our products. Thank you to our veterans and their service to our country.

Opto-Line provides custom optical precision patterns and thin film coatings for companies in the medical, optometry, aerospace, industrial, science and defense sectors. Reach out today to learn more about how we can provide custom solutions for your custom pattern needs.

Since 1967, Opto-Line International has built a reputation for excellence in crafting the the highest quality custom precision optical patterns and thin film coatings available. Pattern Capabilities Using our customers’ specifications, drawings, CAD files, or simply...

Opto-Line Crafts Precision Optometry Optical Patterns for Universities, Visual Science Centers, Eye Institutes, Ophthalmology Schools and more. Call (978) 658-7255 to learn more.

Our team is highly experienced in crafting reticles, ellipses, metrology targets, and many other custom patterns for the Optometry & Opthamology industries. “We are realizing things that Opto-Line can do for us that we never even thought within our reach.” Alfredo...

Opto-Line helps clients across a variety of markets with their custom precision optical patterns. We take great pride in the exceptional quality of our optical patterns and coatings – We invite you to reach out today to learn more about how we can help.

Combined with our specialized photolithography, Opto-Line utilizes thin film coatings to make your custom patterns. Some examples of our custom patterning capabilities include reticles, resolution test targets, EMI grids, apertures, linear scales, and neutral density...

Custom reticles for siting devices and scopes are one of Opto-Line’s most popular project requests

The high level of quality achieved during the manufacturing of our custom reticles is a source of great pride. In addition, careful handling of these sensitive optical components is of paramount importance to every employee of Opto-Line. To learn more about the many...

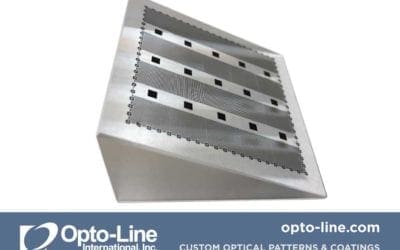

Opto-Line International once again delivers with a custom optical pattern on a prism that other companies could not, or would not, attempt.

With precision, accuracy, and perfection, Opto-Line utilized its proprietary low-reflecting black chrome to create a very detailed image on these prisms used to validate the resolution of optical systems. [button link="https://opto-line.com/" type="big"...

Opto-Line develops precision optical patterns and the highest quality aperatures for the medical device industry including those in the fields of Endoscopy, Optometry and Opthamology.

Our precision Optometry Optical Patterns and Endoscope Apertures have become the benchmark for industry manufacturers. Opto-Line works with Universities, Visual Science Centers, Eye Institutes, Ophthalmology Schools, and more. Reach out today for more information or...